TM 5-3820-246-l4&P

2-7. PMCS INSTRUCTIONS (CONT).

g. When you do your Preventive Maintenance, take the proper tools needed to make all checks. Always take clean

rags with you.

h. Keep working area and tools clean. Dirt, grease, oil, and debris only get in the way and may cover up a serious

problem. Use soap and water to clean as you work and as needed.

i. Check for loose, missing, bent or broken nuts and screws. Check for chipped paint, bare metal or rust around

screw heads. Tighten loose screws or report it to unit maintenance if you are unable to tighten it.

i- Check for loose or chipped paint, rust or gaps where parts are welded together. Report bad welds to unit

maintenance.

k Check for cracked or broken insulation, bare wires and loose or broken connectors. Tighten loose connectors.

Make sure wires are in good shape.

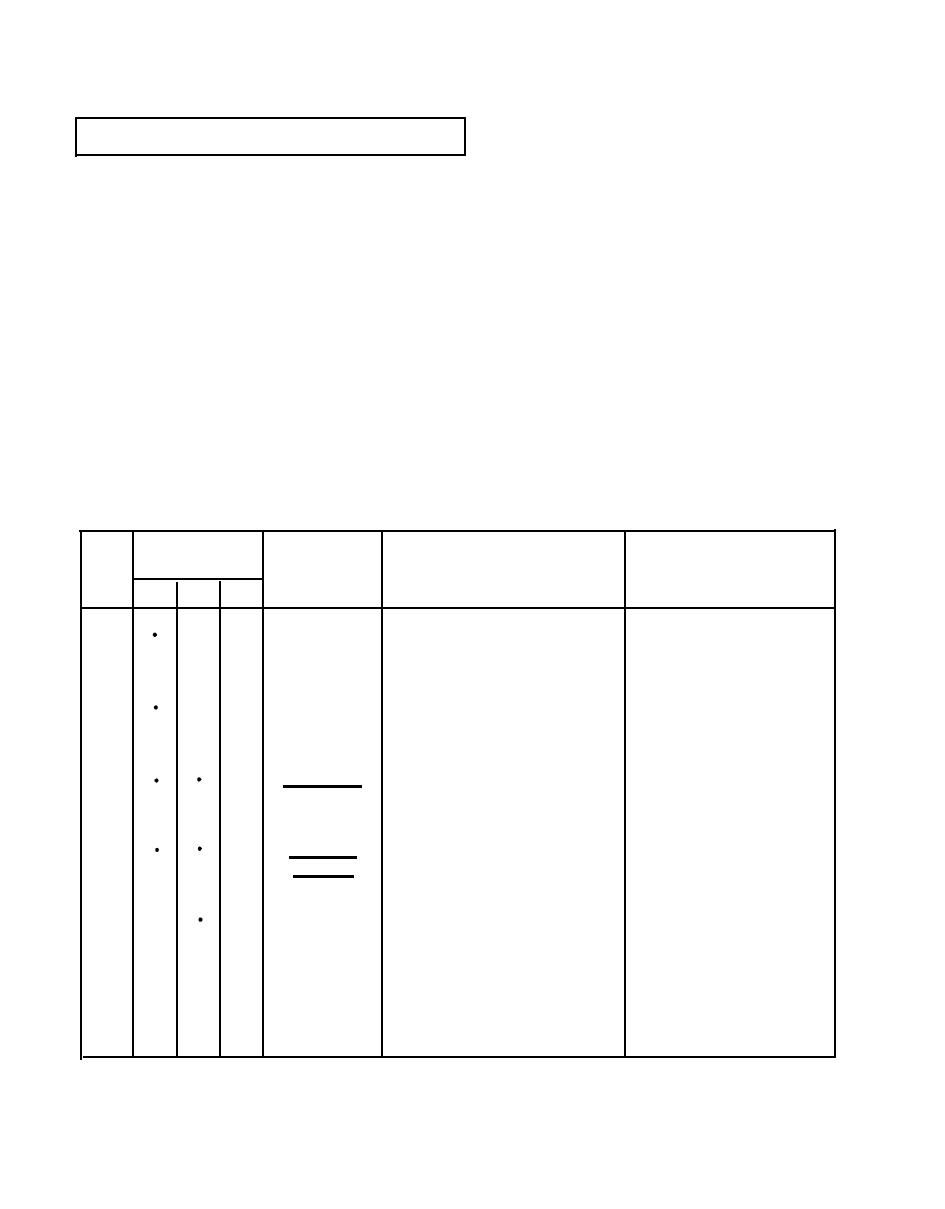

NOTE: Within designated interval, these checks are to be performed in the order listed.

A - After

D - During

B - Before

Equipment Is Not

Procedure: Check for

Ready/Available

and have repaired or adjusted

Item to Be

Interval

Item

If:

as necessary

A Inspected

No.

B

D

Unit is structurally damaged.

a. Visually check for any structural

Body

1

damage that impairs security or

operation of unit.

b. Visually check for missing or

loose nuts, screws, and washers.

Tighten as necessary.

Visually check for cracks, leaks, or

Any leakage of fuel is noted.

Fuel System

2

dents in visible fuel components.

3

Tool holder not holding tool

a. Install tool and operate tool

Front End

properly.

holder to ensure it holds tools

Assembly

properly.

Mode selector not staying in

b. Operate check mode selector to

selected position.

ensure it stays in the selected mode

position.

Rod can be turned CCW.

c. Install tool and try to rotate tool

shaft CCW (as viewed from drive

end).

2-4